In the quest for sustainable and profitable business, individuals have to make continuous incremental improvements. The aim is to reduce or eliminate all types of waste and mistakes. We understand that mistakes will happen and inefficiencies will creep in. Often, we believe that we simply understand the cause of the problem and can rush in to fix it. Unfortunately, it has been found many times that the same problems tend to resurface. The fundamental reason for re-occurrences is that the individual did not actually solve the problem, but rather merely addressed a symptom. This blog is a continuation from our previous blog on Kaizen and FIVE WHY. It highlights another problem-solving tool within Kaizen known as the “Cause-and-Effect analysis”, “Fishbone” or “Ishikawa” diagram.

Cause and Effect explained

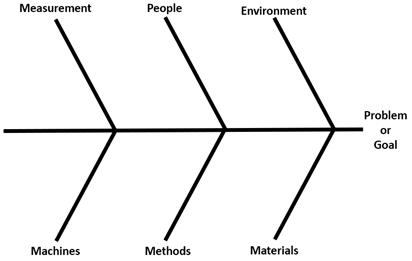

As explained in our “FIVE WHY analysis” article, most people tend to quick fix problems rather than dealing with understanding its root cause. As such, many do not seek to understand how to prevent or reduce the likelihood of re-occurrences. In order to permanently fix a problem, one must understand the root cause of the problem – otherwise one is taking actions to only treat the symptoms. Similar to FIVE WHY, cause-and-effect is another technique used to find root causes. Cause-and-effect looks at various contributors via the use of the diagram below. Each aspect of the diagram is used to brainstorm possible causes under the different headings.

At the head of the ‘fish’ we state the problem (the effect we are experiencing). Each of the ‘bones’ of the fish represents the potential causes of the effect we are experiencing. By this design, the name of this technique is also known as the “fishbone” diagram. Each bone is further broken up into sub-elements to aid in the brainstorming process. Therefore, the potential cause of the effect will sit under one of the headings.

Once the brainstorming exercise is exhausted and potential causes identified, the next step for the team is to work through each possible cause. This exercise must result in the team either agreeing or disagreeing that the possible cause is valid or not. If not, valid they are scratched out. Note that you only remove or scratch out a possible cause if you have facts to support this action.

Once you have narrowed down the possible causes to those that are potentially the biggest causes, you and your team need to investigate each one to understand the root cause (apply FIVE WHY) followed by brainstorming: “How to fix?” This process will result in an action plan of activities and investigations which will need to be closed out. It is important that the action plan has proper action descriptions, due-dates and who is responsible. Often, everyone is excited to do brainstorming, however implementation fails – which leads to the team back at square one and blaming the tools for not working.

One important note to remember is that this technique may be applied on an individual level for simple problems, however it should be implemented as a team-based problem-solving approach to achieve maximum benefits. The team must be made up of individuals with appropriate skills and experience to allow for cross-functionality.

Conclusion

The cause-and-effect tool is marginally more complicated than the FIVE WHY and is used for problems that require more thought and analysis. Cause-and-effect incorporates the FIVE WHY process into it’s methodology. As explained in FIVE WHY, the potential reasons why these techniques may fail are due to:

- The individual believing that they know the answer and hence focusing on fixing symptoms

- Not familiar with the tool and hence it is applied incorrectly

- Not making time to use the tool and to reflect on the cause-and-effect relationships

- FIVE WHY is not done as a team but rather by one person (normally biased)

- The words are not supported by data. Like all good investigators (detectives) what is presented must be supported by evidence.

If you want improvements in your business, start small. Build capability within your business on these techniques and give people the space to apply them. Encourage individuals to make and learn from their mistakes. Be sure that mistakes are not repeated as this implies minimal learning and minimal continuous improvement.

I often come across businesses and individuals that cannot do “continuous improvement” work because they are too busy fighting fires and have empty promises to implement these techniques as soon as they can find time. The caveat of that approach is that continuous improvement actually saves time and allows businesses to focus on other areas.

Author

Dr Kenneth Moodley is an experienced supply chain and business professional with over 25 years’ experience. As someone who has applied systems dynamics and systems thinking he is well placed to support organisations on their journey. He has a demonstrated history of working with both big corporates (example: Unilever & The South African Breweries) and SMME’s (Productivity SA) in various industry sectors as a senior Supply Chain Specialist, Leader and Business Coach. In addition to his supply chain experience, he is a skilled business turnaround strategist and is a registered senior business rescue practitioner.