The Kaizen journey for continuous advancement is made up of incremental improvements every day. It acknowledges that mistakes happen and things go wrong. Individuals should learn from these experiences to figure out how to reduce or prevent the same mistakes. Today’s blog is a continuation from our previous blog on Kaizen and specifically focuses on a particular tool within Kaizen known as “5 WHYs”. It is a terrific basic tool to drive operational efficiency via incremental improvements.

5 WHY’s explained

When faced with a negative situation or fire, the natural reaction of most people is to put out the flame (quick-fix the problem) and then move to the next fire. Most never seek to understand how to prevent or reduce the likelihood of the re-occurrences. In order to permanently fix a problem, one must understand the root cause of the problem – otherwise one is taking actions to only treat the symptoms. The 5 WHY’s are a technique used to uncover the root cause followed by asking: “How do I fix it?”

The 5 WHY’s is the process to ask ‘why’ five times (this is a guideline – one may ask many more or less) with the aim of exploring the cause-and-effect relationships that created the problem. If done correctly, the root cause becomes apparent. Each time you ask WHY and record the answer, that answer becomes the basis for the next WHY. As a rule of thumb: if whilst asking the WHY’s you feel there is repetition and duplication (and you start to feel silly), then you are probably on the right track. One key to be aware of is to not go into the process and assume you already know the answer – this happens often and leads to actions to remedy the symptoms and not the root cause. The 5 WHY technique gets blamed for not being effective, however this is because it is being applied incorrectly.

Practical example

Picture this scenario – you run out of fuel and get stuck while on the way to a client (we will use the lack of fuel as an illustrative example for a vehicle getting stuck). The first reaction – which is correct – is to get fuel and to get moving. There is nothing wrong with this approach, however let’s apply the 5 WHY’s approach to dig deeper into this issue to ensure it never happens again.

In the definition of 5 WHY, we explained that this technique helps us understand cause-and-effect relationships. The obvious effect is that the vehicle is stuck and you miss the appointment. Let’s use the 5 WHY approach to find the root cause:

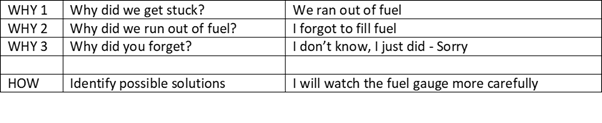

What normally happens (the wrong way to use 5 WHY)?

Guess what? You are probably going to get stuck again. The above solution may work for a while, however this is only a symptom that is caused by the real root cause. Let us try again and ask some deeper questions and get more detailed answers:

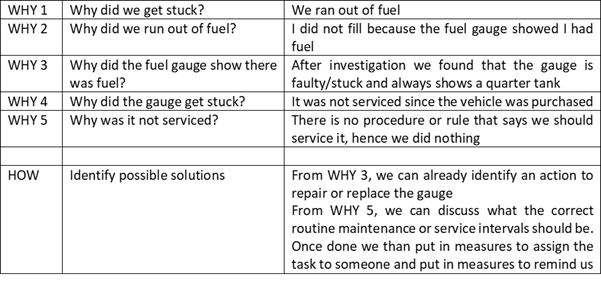

What should happen (the right way to use 5 WHY)?

This is an example of one application. Note that when asking the WHY’s if the possible answers could lead you down multiple paths to investigate. Hence having a team-based approach with the correct skills and experience together with evidence based discussions is crucial.

Conclusion

As observed, the 5 WHY tool is a simple yet powerful method to make incremental improvements. It is shown how easily it is to use this method incorrectly. There are multiple reasons for this:

- The individual thinking they know the answer and hence focusing on fixing symptoms

- Not familiar with the tool and hence it is applied incorrectly

- Not making time to use the tool and to reflect on the cause-and-effect relationships

- 5 WHY is not done as a team but rather by one person (normally biased)

- The words are not supported by data. Like all good investigators (detectives) what is presented must be supported by evidence.

So, if you want to see improvements in your business, start small. Build capability within your business on these techniques and give people the space to apply them. For some insights on how to start small, be sure to check out our blog:

I often come across businesses and individuals that cannot do “continuous improvement” work because they are too busy fighting fires and have empty promises to implement these techniques as soon as they can find time. The caveat of that approach is that continuous improvement actually saves time and allows businesses to focus on other areas. 5 WHY and many other continuous improvements methodologies have been tried and tested. Trust me, it works in organizations of all sizes.

Author

Dr Kenneth Moodley is an experienced supply chain and business professional with over 25 years’ experience. As someone who has applied systems dynamics and systems thinking he is well placed to support organisations on their journey. He has a demonstrated history of working with both big corporates (example: Unilever & The South African Breweries) and SMME’s (Productivity SA) in various industry sectors as a senior Supply Chain Specialist, Leader and Business Coach. In addition to his supply chain experience, he is a skilled business turnaround strategist and is a registered senior business rescue practitioner.